Eclipse Furnnox

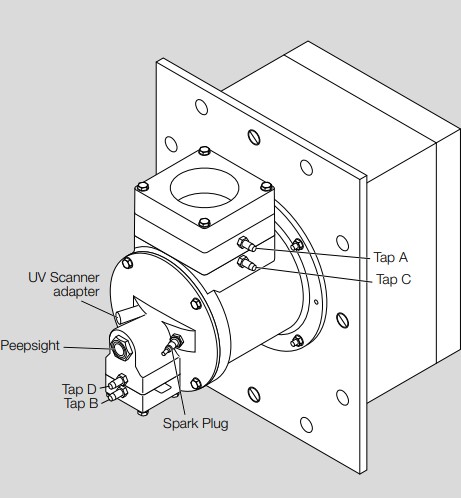

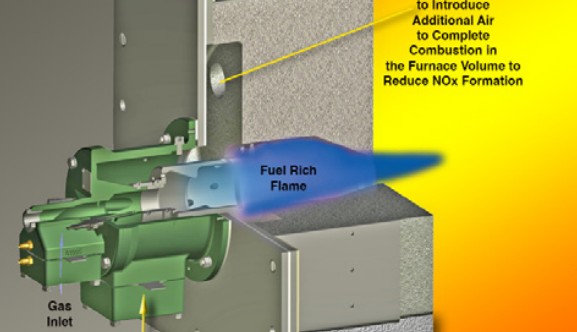

The Eclipse Furnnox burner is a direct fired furnace burner designed for continuous high-temperature processes—such as in the steel industry—offering exceptionally low emissions. In most high-temperature applications, Furnnox burners can achieve NOx emissions below 30 ppm at 3% O₂. To ensure optimal efficiency, the burner maintains the correct air-to-fuel ratio across its full operating range. It is available in two configurations: a standard version for combustion air preheated up to 150°C, and a high-temperature version with an insulated housing, capable of handling preheated air up to 600°C. The Furnnox supports direct ignition throughout its full ignition and operating range without requiring a pilot light. Typical applications include electroplating furnaces, forging furnaces, and heat treatment furnaces. To achieve low NOx emissions, the combustion chamber must operate with less than 5% O₂. Reducing excess air and lowering oxygen levels in the chamber further improves NOx performance.

Features and Benefits:

Documentation:

Features and Benefits:

- NOx emissions < 30ppm (at 3% O2) in most high temperature oven applications

- Power from 66 kW to 530 kW

- Turndown up to 10:1

- Max. process temperature: 1540°C

- Preheated air up to 150°C in standard version

- Pre-heated air up to 600°C with specially insulated housing

- Fuel: natural gas, propane, butane

Documentation:

Didn't find what you were looking for?

Are you looking for a specific item that you cannot immediately find here? Feel free to contact us – we will be happy to help you further and find the right solution together!